Radio Frequency Identification (RFID) technologies have come a long way since their original designs, which were meant to identify aircraft as friend or foe during World War II. The first true predecessor of modern RFID received a patent in 1973 and showed promise to select industries such as transportation, banking, security, and healthcare. Specific applications such as automatic toll systems, electronic credit cards, and personnel identification were just the beginning of a technological revolution that touches nearly every sector of today’s society.

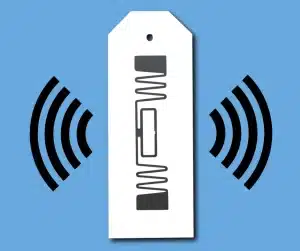

How Do RFID Tags Work?

RFID belongs to a broad technological grouping called Automatic Identification and Data Capture (AIDC). This includes technologies such as QR and bar codes, biometric identification, and voice recognition. Each method automatically identifies objects, images, light, or sounds and collects their data, storing it directly into a digital system without any human involvement. RFID systems accomplish this using radio waves in either a passive or active capacity. Passive RFID tags require power from the reading device in order to transmit their stored data, and so remain effectively inactive until someone reads them. Active RFID tags contain their own source of power and electronics which allows them to consistently transmit data—and at much greater distances than passive tags. Both types have their ideal applications, but industries more commonly use passive tags as they are typically smaller and less expensive to use in large scale operations.

What are the Benefits of RFID?

Barcodes are rapidly becoming obsolete. When it comes to improving operational efficiency, RFID technologies are unrivaled in their effectiveness. While barcodes allow businesses to track their inventory at fixed intervals, RFID can track just about anything, including forklifts, supply trucks, and other valuable assets that pass through a facility—all continuously in real-time. This provides invaluable and solid insights into the status of a diverse range of concerns, which ultimately prevents errors, streamlines business processes, and leads to better and more accurate business decisions.

How does RFID Technology work?

Radio frequency identification technology is an automatic way to collect product data quickly and easily. An RFID system comprises a reader (or interrogator), its associated antenna and the transponders (or tags) that carry the data. The reader transmits a low-power radio signal, through its antenna, that the tag receives via its own antenna to power an integrated circuit (chip). Using the energy it gets from the signal when it enters the radio field, the tag will briefly converse with the reader for verification and the exchange of data (or the Electronic Product Code). Once that EPC data is received by the reader it can be sent to a controlling computer for processing and management.

What are the advantages of RFID

1. RFID technology does not require line-of-sight reading.

2. RFID tags can hold more data than bar codes.

3. RFID tag data can be changed or added to as a tag passes through specific operations.

4. RFID tags are more effective in harsh environments where bar code labels have problems.

Are Starport Technologies RFID products active (tags with batteries) or passive (tags without batteries)?

The products that are currently offered by Starport Technologies are all passive UHF Class 1 Gen2 transponders. With recent technological developments passive RFID capabilities are quickly approaching the more expensive active tags.

What is the difference between high and ultra-high frequencies?

RFID systems use many different frequencies, but generally the most common are high- (13.56 MHz) and ultra-high frequency, or UHF (902-928 MHz). RFID tags and readers have to be tuned to the same frequency to communicate. Different frequencies have different characteristics that make them more useful for different applications. For instance, low-frequency tags are cheaper than ultra high frequency (UHF) tags, use less power and are used in close range scanning. UHF frequencies typically offer better range and can transfer data faster.

Does Starport Technologies offer a global tag, one that works with the different frequencies of other countries?

Due to the complexity of the interaction of the antenna with the components of the tags to achieve optimum performance in read range and speed of data transfer, each frequency needs to be match to a uniquely tuned antenna. Starport currently offers RFID inlays and products that perform in every country of the world.

What are the actual read and write ranges for a typical RFID tag?

The read range of passive tags (tags without batteries) depends on many factors: the frequency of operation, the power of the reader, interference from metal objects or other RF devices. In general, high frequency tags are read from about three feet and UHF tags are read from 5 to 100 feet. The write range is based upon the type and size of the transponder. It can range between 40 to 80% of the read distance.

The ability to read an RFID device is greatly reduced when mounted on liquids and metals.

Why can Starport Technologies RFID products be read on metal or liquids?

The antenna is designed and tuned to work in conjunction with the properties of each of the internal components which comprise the structure. Remove or alter any one of the components and the tag will not perform at its designed performance level. The interaction of each component with the total package is vital.

What is the read range of Starport Technologies RFID products?

The antenna is designed and tuned to work in conjunction with the properties of each of the internal components which comprise the structure. Remove or alter any one of the components and the tag will not perform at its designed performance level. The interaction of each component with the total package is vital.

What IC is currently being used by Starport Technologies?

Both Monza and Alien “Higgs” IC are used. The Monza and Alien “Higgs 2” are both EPC Class 1 Gen 2 with EPC memory of 96 bits. Starport Technologies also can offer Alien “Higgs 3” a EPC Class 1 Gen 2 IC with user memory of 512 bits.

How is the tag attached or mounted?

An acrylic based pressure sensitive adhesive is laminated to back side of the tags. If a mechanical mount is required these tags can be mounted by bolting, riveting, screwing, or tying with wires.

How rugged are these tags?

The components that comprise the tags are materials that have been selected due to there ability to meet the requirements for outdoor exposure. The Portunus and Terminator metal-mount tags are the most rugged able to with stand outdoor exposure for several years. The Terminator, Adamas and Orion can be used outdoors but their life expectance in an outdoor environment would be approximately one year. When the tags are used indoors all four tags will offer many years of service. Supply chain tags are generally not as rugged but and are considered “disposable” after they are utilized throughout the supply chain.

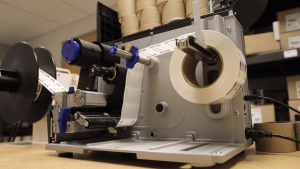

Can the tags be printed?

Due to the converting of the tags being done on a Nilpeter flexographic web printing press the surface of the tag can be printed. An example of the printing could be a company logo, ID numbers, or bar codes. This is generally referred to as RFID Encoding Service.